RECOVERY OF RUBBER WASTE

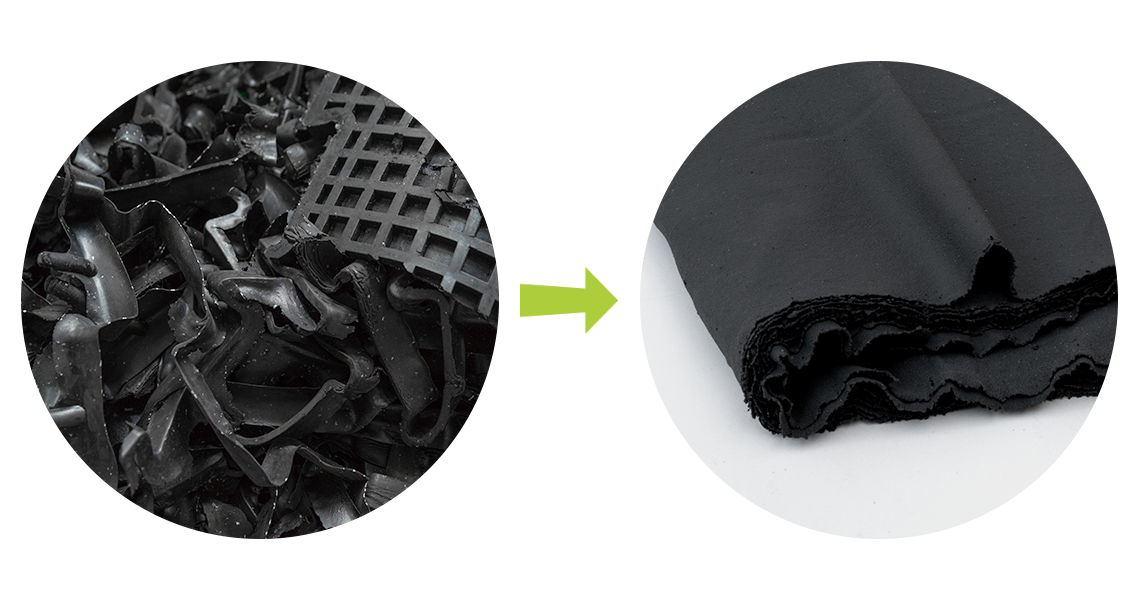

We convert waste into quality “virgin” rubber.

We recover your rubber waste, converting it again into recycled “virgin” rubber that you can use again in your production.

The process

- Reception of rubber waste

- Recycling (devulcanization)

- Return of recycled “virgin” rubber

- Reintegration in the production of rubber articles

What is devulcanization?

This treatment reverses the vulcanization process of the rubber, obtaining a recycled rubber that can be incorporated back into production as if it were virgin rubber.

This innovative process – devulcanization – is done without chemical additives. It’s only thermomechanical. Therefore, the recycled material obtained has exactly the same characteristics as the rubber formulation that in its origin, namely its color or REACH certification.

Devulcanized rubber can be supplied in blanket or powder.

%

of the formulation can incorporate devulcanized rubber

Advantages of devulcanized rubber:

Abundant raw material

Total reuse of its rubber waste

Ecological, recycled and recyclable material.

Maintains the characteristics of the original rubber.

Lower cost than virgin raw material.

Price stability (does not fluctuate with markets)

Significant environmental contribution

The process can be repeated infinitely

Circular economy

Ask for a sample

Rubberlink supplies devulcanized rubber in blanket or powder.

Ask for a sample now and check its quality.

Ask for a sample now and check its quality.