SUSTAINABILITY

Each year, more than 1 billion scrap tires are produced globally. The management of rubber waste – and tires in particular – is a major environmental problem and one of the greatest challenges of the century.

The routing of rubber to landfill or its combustion for power generation are not environmentally friendly solutions and, above all, they’re not sustainable.

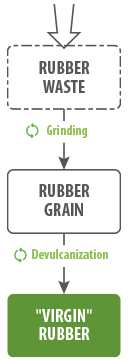

Rubber recycling by devulcanization

The best way to eliminate rubber waste is by recycling it through devulcanization. Through this process we obtain a “virgin” product that can be reused for its original purpose, allowing its reintroduction in the production cycle and contributing to an infinite and sustainable circular economy. Devulcanization is the highest form of recycling, making rubber a 100% renewable resource.

This state-of-the-art rubber enhancement technology helps to

- Recycle the world stock of rubber waste, including tires.

- Reuse recycled rubber in the production of new products without sacrificing quality.

- Reduce world dependence on oil.

Advantages for the environment

1.

Reduced consumption of synthetic rubber

a non-renewable oil-based resource.

2.

Less air pollution

more than half of all scrap tires are burned.

3.

Less environmental hazards

associated with the placement in landfills of tires and other polluting rubbers.

Ask for a sample

Rubberlink supplies devulcanized rubber in blanket or powder.

Ask for a sample now and check its quality.

Ask for a sample now and check its quality.